TMC4671 is based on hardware FOC servo control chip to adapt to BLDC-PMSM, two-phase stepper, DC brush, voice coil motor

Time:2023-08-22

Views:739

TMC4671 is a fully integrated servo control chip that provides field oriented control for DC brushless motors, permanent magnet synchronous motors, 2-phase stepper motors, DC brushless motors, and voice coil motors.

All control functions are integrated into the hardware. This fully functional servo controller integrates ADCs, position sensor interfaces, and position differentiators, suitable for various servo applications.

Function Introduction:

·Servo control chip, space magnetic field vector control (FOC)

·Torque Control (FOC), Speed Control, Position Control

·Feedforward control input

·Integrated ADCs, front-end Δ∑ ADCs

·Encoder engine: analog and digital Hall, analog and digital encoders

·Supports three-phase DC brushless servo and permanent magnet synchronous servo motors, 2-phase stepper servo motors, DC brushless and voice coil motors

·Advanced PWM engine (25KHz... 100KHz)

·Application SPI+Debugging (UART, SPI)

·Pulse/direction interface

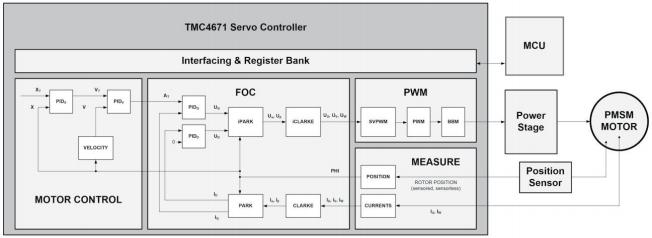

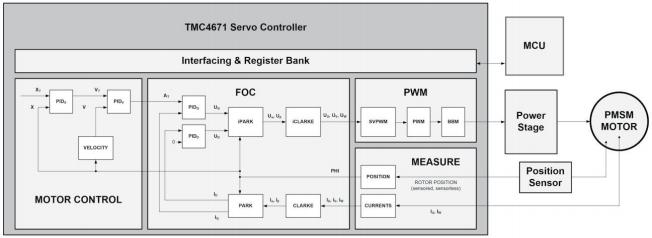

Hardware FOC Block Diagram

Performance description:

● Servo control chip with magnetic field vector control (FOC)

·Torque control mode

·Speed control mode

·Position control mode

·The current control refresh frequency and maximum PWM frequency are 100KHz (the refresh frequency for speed and position control can be configured based on multiples of the current current refresh frequency)

● Control function/PI controller

·Programmable chopping for input and output of mid-term results

·Protect all controls with integral circuit ending

·Programmable voltage cycle guide limiter

·Feedforward compensation and feedforward friction compensation for target values

·Advanced feedforward control structure for optimal trajectory tracking performance

·Extended Interrupt Request Masking Options and Limiter Status Registers

·Advanced encoder initialization algorithm with Hall sensor or/and minimum movement

● Motion control and slope control

·Control the trapezoidal speed slope of the structure

·Pulse/directional interface for easy positioning

● Supported motor types

·FOC3: three-phase permanent magnet synchronous servo motor (PMSM)

·FOC2: Two phase stepper motor

·DC1: DC brush motor or linear voice coil motor

● ADC engine with offset correction and scaling functions

·Integrated Δ∑ ADCs for current detection voltage, motor power supply voltage, and analog encoder

·Integrated Δ∑ interface for external Δ∑ regulation

● Position feedback

·Open loop position generator (programmable PRM, RPM/S) for initialization configuration

·Digital incremental encoder (ABN, ABZ up to 5MHz)

·Second digital encoder input (dual feedback)

·Digital Hall input interface with temporary position interpolation function (H1, H2, H3 resp. HU, HV, HW)

·Analog encoder/analog Hall input interface (SinCos (0 °, 90 °) or 0 °, 120 °, 240 °)

·Target position, speed, and target torque filtering (second-order)

● PWM includes SVPWM

·Programmable PWM frequency range from 20KHz-100KHzinc

·Programmable BBM (Brake Before-Make) time (low, high) 0 ns 2.5_ Within 10 ns steps and with the gate

● Drive input signal

·PWM automatic adjustment for changing PWM frequency during movement

● SPI communication interface

·40 bit data length (1 ReadWrite bit+7 address bits+32 data bits)

·Immediate SPI read response (register read access through a single datagram)

·SPI clock frequency up to 1 MHz (future version will be 8 MHz)

● TRINAMIC real-time monitoring interface (SPI Master)

·Real time data high-frequency sampling achieved through TRINAMIC‘s real-time monitoring system

·Requires a single 10 pin high-density connector on a PCB

·Advanced controller supports TRINAMIC IDE adjustment through frequency response recognition and advanced automatic tuning support

● UART debugging interface

·3-pin (GND, RxD, TxD) 3.3V UART interface (1N8; 9600 (default), 115200, 921600, or 3M bps)

·Simple Register Access Parallel to Embedded User Application Program Interface (SPI)

● Power supply voltage: 5V and 3.3V; 1.8V VCC_ CORE is generated internally

● IO voltage: 3.3V for all digital I/O (selectable by VCCIO); 5V plug-in analog input range, 3V for single ended input range

● Clock frequency: 25MHz (requires external oscillator)

● Packaging: QFN76

|

Disclaimer: This article is transferred from other platforms and does not represent the views and positions of this site. If there is any infringement or objection, please contact us to delete it. thank you! |