How to choose the appropriate LDO for portable products

Time:2022-05-25

Views:2144

Grounding current or quiescent current (ignd or IQ), power ripple rejection ratio (PSRR), noise and package size are usually the factors that determine the best LDO selection for portable applications. When selecting low dropout linear regulator (LDO), the basic problems to be considered include input voltage range, expected output voltage, load current range and power consumption capacity of its package. However, portable applications need to consider more issues.

Input, output and voltage reduction

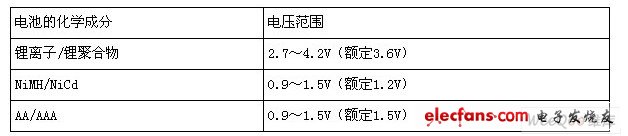

Selecting the input voltage range can adapt to the LDO of the power supply. The following table lists the voltage range of popular battery chemicals used in portable devices.

When determining whether LDO can provide the expected output voltage, its voltage drop needs to be considered. The input voltage must be greater than the sum of the expected output voltage and the specific voltage drop, i.e. VIN Vout + vdropout. If the VIN drops below the required voltage, we say that the LDO has a "voltage drop", and the output is equal to the input minus the RDS (on) of the pass element multiplied by the load current.

It is necessary to pay attention to the performance change during pressure drop. The error amplifier that drives the bypass transistor is fully on or "cocked", so no loop gain is generated. This means poor line and load regulation. In addition, PSRR also decreases significantly at pressure drop.

LOD that can provide the expected output voltage is selected as a fixed option to save the cost and space of external resistance voltage divider. External resistance voltage divider is generally used to set the output voltage of adjustable devices. With adjustable LDO, the output can be set to provide internal reference voltage, which is generally about 1.2V. Only connect the output to the feedback pin. Please confirm with the manufacturer whether it has this function.

Load current requirements

By considering the amount of current required by the load, LDO is selected accordingly. Please note: LDO with rated current of 150mA, for example, may provide much higher current in a short time. Please check the minimum output current limit specification, or consult the relevant manufacturer.

Battery voltage

Packaging and power consumption

Portable applications are inherently space constrained, so the size of the solution is crucial. Bare chips can minimize size, but lack many advantages of packaging, such as protection, industry standards and easy adoption by existing assembly architectures. Chip level packaging (CSP) can not only provide the size advantage of bare chip, but also bring many advantages of packaging.

Driven by the market demand for wireless handheld terminals, CSP products are constantly innovating. For example, Texas Instruments (TI) 200mA RF LDO with 0.84 x 1.348-mm CSP uses technology that enables easy assembly and high board level reliability.

Compared with SOT-23 and SC-70 packaging, LDO with chip level packaging has both advantages of bare chip size and packaging

Other small packages include the popular 3x3mm SOT-23 and small 2.13x2 3mm SC-70, sub-1-mm-height package, thinspot and leadless Quad flatpack (QFN). QFN can provide better heat dissipation characteristics due to the use of a heat dissipation pad on the lower side that can establish an efficient heat dissipation contact between the device and the PC board.

Be careful not to exceed the maximum power consumption rating of the package. The power consumption can be calculated by pdissipiation = (Vin-Vout) / (IOUT + IQ). Generally speaking, the smaller the package size, the smaller the power consumption. However, QFN package can provide excellent heat dissipation performance, which can be comparable to many packages with a size of 1.5 ~ 2 times.

LDO topology and IQ

In order to maximize the running time of the battery, LDO with low quiescent current IQ relative to the load current needs to be selected. For example, considering that IQ only increases the insignificant battery consumption by 0.02%, 200 is generally used under 100mA load μ A‘s IQ is reasonable.

In addition, it should be noted that due to the discharge characteristics of the battery, the voltage drop will have a decisive impact on the battery life in some cases. Due to the slow discharge speed of alkaline battery, its power supply voltage can provide more capacity than NiMH battery under voltage drop. A careful trade-off between IQ and voltage drop must be made in order to obtain the maximum capacity during the battery life, so a lower IQ does not always guarantee a long battery life.

In addition, attention should be paid to how IQ is specified in the data sheet. Some devices are specified at room temperature or only provide a typical curve showing the relationship between IQ and temperature. Although these conditions are useful, the maximum quiescent current is not guaranteed. If IQ is important, it is necessary to select devices that can ensure IQ under all load, temperature and process variables, and MOS bypass devices.

Output capacitor

Typical LDO applications require the addition of external input and output capacitors. Selecting LDO that does not require the stability of capacitor can reduce the size and cost, and these components can be completely eliminated. Note that large capacitors with lower ESR can generally improve PSRR, noise and transient performance.

Ceramic capacitors are usually preferred because they are cheap and the failure mode is open circuit. In contrast, tantalum capacitors are expensive and their failure mode is short circuit. Please note that the equivalent series resistance (ESR) of the output capacitor will affect its stability. The ceramic capacitor has a low ESR of about 10 haoohm, while the tantalum capacitor has an ESR of 100 haoohm. In addition, the ESR of many tantalum capacitors varies greatly with temperature, which will adversely affect the performance of LDO. If the temperature changes little and a proper resistance (generally 200m) is connected in series between the capacitor and the grounding, tantalum capacitor can be used instead of ceramic capacitor. LDO manufacturers need to be consulted to ensure correct

implementation.

RF and audio applications

Finally, the power requirements of special circuits used in portable applications are considered.

RF circuits (including LNA (low noise amplifier), step-up / step-down converter, mixer, PLL, VCO, if amplifier and power amplifier) need LDO with low noise and high PSRR. Great care should be taken when designing modern transceiver systems to ensure low noise and high linearity.

Power supply noise will increase the phase noise of VCO and enter the receiving or transmitting amplifier. When popular mobile phone technologies such as W-CDMA put forward strict requirements for spectrum regeneration and adjacent channel power, a very small amount of power supply noise entering the base / gate or collector / drain power supply of the amplifier will produce adjacent channel noise or false signal.

In order to meet the audio requirements of portable devices such as mobile phones, MP3, games and multimedia PDA applications, an LDO of 300 ~ 500mA may be required. Moreover, in order to obtain good audio quality, this LDO should be low noise and provide high PSRR at audio frequency (20Hz ~ 20kHz).

|

Disclaimer: This article is transferred from other platforms and does not represent the views and positions of this site. If there is infringement or objection, please contact us to delete. thank you! |