Capacitor selection rules in power supply design

Time:2022-09-09

Views:1793

abstract

Power supply is often the most neglected link in the process of circuit design. As an excellent design, power supply design should be very important, which greatly affects the performance and cost of the whole system. The use of capacitors in power supply design is often the most easily ignored place in power supply design.

1、 Working principle of capacitor in power supply design

In power supply design applications, capacitors are mainly used for filter and decoupling / bypass. Filtering is the operation of filtering the frequency of a specific band in the signal, and it is an important measure to suppress and prevent interference. The probability theory and method of estimating another related random process according to the results of observing one random process. The term "filtering" originated from the communication theory. It is a technology to extract useful signals from the received signals containing interference. "Received signal" is equivalent to the observed random process, and "useful signal" is equivalent to the estimated random process.

Filtering mainly refers to filtering out external noise, and decoupling / bypass (one is to achieve decoupling effect in the form of bypass, which will be replaced by "decoupling" later) is to reduce external noise interference of local circuits. Many people easily confuse the two. Let‘s look at a circuit structure:

The power supply in the figure supplies power to a and B. After passing through C1, the current passes through a section of PCB wiring and is divided into two paths to supply a and B respectively. When a needs a large current at a certain moment, if there are no C2 and C3, the voltage at terminal a will become low due to the line inductance, and the voltage at terminal B will also be reduced due to the voltage at terminal A. therefore, the current change of local circuit a causes the power supply voltage of local circuit B, thus affecting the signal of circuit B. Similarly, the current change of B will also interfere with a. This is called "common path coupling interference".

After adding C2, when the local circuit needs another instantaneous large current, the capacitor C2 can temporarily provide current for A. even if there is a common inductance, the voltage at terminal a will not drop too much. The impact on B will also be much reduced. Thus, decoupling is achieved by current bypass.

General filtering mainly uses large capacity capacitors, which do not require fast speed, but require high capacitance. If the local circuit a in the figure refers to a chip, and the capacitance is as close to the power pin of the chip as possible. If "local circuit a" refers to a functional module, ceramic chip capacitors can be used. If the capacity is insufficient, tantalum capacitors or aluminum electrolytic capacitors can also be used (provided that all chips in the functional module have decoupling capacitors - ceramic chip capacitors).

The capacity of the filter capacitor can often be calculated from the data book of the power chip. If the filter circuit uses electrolytic capacitor, tantalum capacitor and porcelain chip capacitor at the same time, place the electrolytic capacitor nearest to the power off, so as to protect the tantalum capacitor. The ceramic chip capacitor is placed behind the tantalum capacitor. In this way, the best filtering effect can be obtained.

Decoupling capacitor needs to meet two requirements, one is capacity requirement and the other is ESR requirement. That is to say, the decoupling effect of one 0.1uF capacitor may not be as good as that of two 0.01uF capacitors. Moreover, the 0.01uF capacitor has a lower impedance in the higher frequency band. If a 0.01uF capacitor can meet the capacity requirement in these frequency bands, it will have a better decoupling effect than a 0.1uF capacitor.

Many high-speed chip design guidance manuals with more pins will give the requirements for decoupling capacitors in power supply design. For example, a BGA package with more than 500 pins requires that the 3.3V power supply should have at least 30 porcelain chip capacitors and several large capacitors, with a total capacity of more than 200uf

2、 Correct selection of capacitors in various power supplies

As a basic component, capacitors play an important role in electronic circuits. In traditional applications, capacitors are mainly used for bypass coupling, power filtering, DC isolation, oscillation and delay in small signals. With the development of electronic circuits, especially power electronic circuits, different special requirements are put forward for capacitors in different applications.

From the structure of the capacitor. The simplest capacitor is composed of plates at both ends and insulating dielectrics (including air) in the middle. After energization, the electrode plate is charged to form a voltage (potential difference), but because of the insulating material in the middle, the entire capacitor is non-conductive. However, such a case occurs on the premise that the critical voltage (breakdown voltage) of the capacitor is not exceeded. We know that any substance is relatively insulated. When the voltage across the substance is increased to a certain extent, the substance can conduct electricity. We call this voltage the breakdown voltage.

Capacitors are no exception. After a capacitor is broken down, it is not an insulator. However, in the middle school stage, such a voltage can not be seen in the circuit, so it works below the breakdown voltage and can be seen as an insulator. However, in an AC circuit, the direction of the current changes with time in a certain functional relationship. The process of capacitor charging and discharging takes time. At this time, a changing electric field is formed between the plates, and this electric field is also a function of time.

1. Filter capacitor

After AC (power frequency or high frequency) is rectified, it needs capacitor filtering to smooth the output voltage, which requires large capacitor capacity. Generally, aluminum electrolytic capacitors are used. The main problem in the application of aluminum electrolytic capacitors is the relationship between temperature and life, which basically follows the rule of 50 ℃. Therefore, in many occasions requiring high temperature and high reliability, electrolytic capacitors with long service life (such as more than 5000h, even 105 ℃, 5000h) should be selected. Generally, the life of small electrolytic capacitors is relatively short.

Input filter capacitor for DC / DC switching regulated power supply. Since the switching converter draws power from the power supply in the form of pulse, a large high-frequency current flows through the filter capacitor. When the equivalent series resistance (ESR) of electrolytic capacitor is large, it will cause large loss, resulting in heating of the electrolytic capacitor. The low ESR electrolytic capacitor can significantly reduce the heat generated by ripple (especially high-frequency ripple) current.

For electrolytic capacitors used for output rectification of switching regulated power supply, it is required that their impedance frequency characteristics do not show an upward trend at 300kHz or even 500KHz. However, ordinary electrolytic capacitors began to show an upward trend after 100kHz, and the effect of rectifying and filtering the output of switching power supply was relatively poor. The author found in the experiment that 4700 μ F. 16V electrolytic capacitor, which is used for switching power supply output filtering. The ripple and spike are not higher than cd03hf 4700 μ F. The 16V high-frequency electrolytic capacitor is low, and the temperature rise of the ordinary electrolytic capacitor is relatively high. When the load is abrupt, the transient response of ordinary electrolytic capacitors is far worse than that of high-frequency electrolytic capacitors.

Since aluminum electrolytic capacitors can not play a good role in the high frequency range, they should be supplemented by ceramic or non inductive film capacitors with good high frequency characteristics. Their main advantages are: good high frequency characteristics and low ESR. For example, mmk5 has a capacity of 1 μ F capacitor has a resonance frequency of more than 2MHz and an equivalent impedance of less than 0.02 Ω, which is far lower than electrolytic capacitor. The smaller the capacity, the higher the resonance frequency (up to more than 50MHz). In this way, a good output frequency response or dynamic response of the power supply will be obtained.

In filter capacitor, we focus on how to select filter capacitor in switching power supply and how to select filter capacitor in switching power supply.

Filter capacitor plays a very important role in switching power supply. How to correctly select filter capacitor, especially the output filter capacitor, is a very important issue for every engineer and technician.

For ordinary electrolytic capacitors used in 50 Hz power frequency circuits, the pulsating voltage frequency is only 100 Hz, and the charging and discharging time is on the order of milliseconds. In order to obtain a smaller pulsation coefficient, the required capacitance is as high as hundreds of thousands of microfarads. Therefore, the goal of ordinary low-frequency aluminum electrolytic capacitors is to improve the capacitance. The capacitance, tangent of loss angle and leakage current of capacitors are the main parameters to identify their advantages and disadvantages. The output filter electrolytic capacitor in the switching power supply has a sawtooth wave voltage frequency of tens of thousands of Hertz, even tens of megahertz. At this time, the capacitance is not the main index, and the standard to measure the quality of high-frequency aluminum electrolytic capacitors is the "impedance frequency" characteristic. It is required to have a low equivalent impedance within the operating frequency of the switching power supply, and to have a good filtering effect on the high-frequency peak signals generated by the semiconductor devices.

Many electronic designers know the role of filter capacitors in the power supply, but the filter capacitors used at the output of switching power supplies are different from those used in power frequency circuits. The pulse voltage frequency on them is only 100 Hz, and the charge and discharge time is on the order of milliseconds. In order to obtain a small pulse coefficient, the capacitance required is as high as hundreds of thousands of microfarads. Therefore, ordinary aluminum electrolytic capacitors are generally used for low frequencies, The goal is mainly to improve the capacitance. The capacitance, tangent of loss angle and leakage current of the capacitor are the main parameters to identify its advantages and disadvantages.

As an electrolytic capacitor for output filtering in the switching regulated power supply, the frequency of sawtooth wave voltage on it is as high as tens of kilohertz or even tens of megahertz. Its requirements are different from those in low-frequency applications. Capacitance is not the main index. Its impedance frequency characteristic is the measure of its quality. It is required to have a low impedance within the operating frequency band of the switching regulated power supply. At the same time, for the internal part of the power supply, Because the semiconductor device can also filter the peak noise of hundreds of kHz when it starts to work, the impedance of ordinary electrolytic capacitors for low-frequency use generally starts to show inductance at about 10 kHz, which can not meet the requirements of switching power supply.

Ordinary low-frequency electrolytic capacitors begin to show inductance at about 10000 Hz, which can not meet the requirements of switching power supply. The high-frequency aluminum electrolytic capacitor dedicated to switching power supply has four terminals. Both ends of the positive aluminum sheet are led out as the positive electrode of the capacitor, and both ends of the negative aluminum sheet are also led out as the negative electrode. The current flows from one positive end of the four terminal capacitor, passes through the capacitor, and then flows to the load from the other positive end; The current returned from the load also flows from one negative terminal of the capacitor, and then flows from the other negative terminal to the negative terminal of the power supply.

The high-frequency aluminum electrolytic capacitor for switching regulated power supply has four terminals. Both ends of the positive aluminum sheet are led out as the positive electrode of the capacitor, and both ends of the negative aluminum sheet are also led out as the negative electrode. The current of the regulated power supply flows from one positive end of the four terminal capacitor, passes through the capacitor, and then flows to the load from the other positive end; The current returned from the load also flows from one negative terminal of the capacitor, and then flows from the other negative terminal to the negative terminal of the power supply. Because the four terminal capacitor has good high-frequency characteristics, it provides a very favorable means to reduce the ripple component of the output voltage and suppress the switching spike noise.

The switching regulated power supply has multi-functional comprehensive protection: in addition to the most basic stable voltage function, the regulator should also have the most basic protection functions such as overvoltage protection (more than + 10% of the output voltage), undervoltage protection (less than - 10% of the output voltage), phase loss protection and short-circuit overload protection. Sharp pulse suppression (optional): sometimes sharp pulses with high amplitude and narrow pulse width will appear in the power grid, which will break down electronic components with low withstand voltage. The anti surge components of the regulated power supply can suppress such sharp pulses very well.

The high-frequency aluminum electrolytic capacitor is also in the form of multi-core, which divides the aluminum foil into several short sections and connects them in parallel with multiple lead pieces to reduce the resistance component in the capacitance reactance. At the same time, low resistivity materials and screws are used as lead terminals to enhance the capacitor‘s ability to withstand large current.

Laminated capacitor is also called non inductive capacitor. Generally, the core of electrolytic capacitor is rolled into a cylindrical shape, and the equivalent series inductance is large; The structure of the laminated capacitor is similar to that of books. The magnetic flux generated by the current flows in the opposite direction and is canceled, thus reducing the value of the inductance and having better high-frequency characteristics. This capacitor is generally made into a square shape, which is easy to fix, and can also appropriately reduce the occupied volume.

Capacitor step-down power supply circuit

2. Absorption and commutation capacitor

As the rated power of gate controlled semiconductor devices becomes larger and larger, the switching speed becomes faster and faster, and the rated voltage becomes higher and higher, it is not enough to only require sufficient withstand voltage, capacity and excellent high-frequency characteristics for the capacitor of the buffer circuit.

In high-power power electronic circuits, since the switching speed of IGBT has been less than 1 μ s. Required voltage change rate DV / DT on capacitor of absorption circuit (V)/ μ S is already very normal, and some require V/ μ S even V/ μ s。

For common capacitors, especially common metallized capacitors, DV / dt 100V/ μ s. DV / dt of special metallized capacitor ≤ 200V/ μ s. DV / dt of special bimetallic capacitor with small capacity (less than 10nf) ≤ 1500V/ μ s. Large capacity (less than 0.1 μ F) Is 600V/ μ s. It is difficult to withstand such a huge peak current impact with a high repetition rate. Damage to power electronic circuits.

At present, special capacitors for absorption circuits, that is, metal foil electrodes, can withstand large peak current and RMS current shocks, such as 100000v for small capacity (below 10nf)/ μ s~455000V/ μ 3700a peak current and 9A RMS current (such as cdv30fh822j03); Large capacity (more than 10nf, less than 0.47 μ F) Or larger size can withstand more than 3400v/ μ S and 1000 a peak current.

It can be seen that although they are the same non inductive capacitor, metallized capacitor and metal foil capacitor, they will have different performances in the absorption circuit. Similar shapes but different specifications are absolutely not interchangeable here. The size of the capacitor will affect the DV / dt and peak current tolerance of the capacitor. Generally speaking, the larger the length, the smaller the DV / dt and peak current.

The working characteristics of the capacitor in the absorption circuit are that the duty ratio of the high peak current is small, and the effective value current is not very high. Similar to this circuit, there is also the commutation capacitor of the thyristor inverter. Although the DV / dt required by this capacitor is smaller than that of the absorption capacitor, the peak current and the effective value current are both large, and the current of ordinary capacitors cannot meet the requirements.

In some special applications, the energy storage capacitor is required to discharge rapidly and repeatedly, and the resistance of the discharge circuit is very low and the parasitic inductance is very small. In this case, the absorption capacitor can only be used in parallel to ensure the reliability of long-term use.

3. Resonance capacitor

Resonant converters, such as the resonant capacitor in the resonant circuit of resonant switching regulated power supply and thyristor intermediate frequency power supply, often flow a large current when working. Another example is that when the specification of the resonant capacitor of the electronic ballast is not selected properly, the voltage on the capacitor may not reach the breakdown voltage but may be damaged due to a large resonant current.

In a circuit with a capacitor and an inductor, if the capacitor and the inductor are connected in parallel, it may occur in a very small period of time: the voltage of the capacitor gradually increases, but the current gradually decreases; At the same time, the current of the inductor gradually increases, and the voltage of the inductor gradually decreases. In another very small period of time, the voltage of the capacitor gradually decreases, but the current gradually increases; At the same time, the current of the inductor gradually decreases, and the voltage of the inductor gradually increases. The increase of voltage can reach a positive maximum value, and the decrease of voltage can also reach a negative maximum value. Similarly, the direction of current will also change in the positive and negative directions in this process. At this time, we call the circuit generating electrical oscillation.

The phenomenon of circuit oscillation may gradually disappear or may continue unchanged. When the oscillation continues, we call it equal amplitude oscillation, also known as resonance.

Resonance time: the time when the voltage of the capacitor or inductor changes by one cycle is called the resonance period, and the reciprocal of the resonance period is called the resonance frequency. The resonance frequency is defined in this way.

To sum up, in modern power supply technology, capacitors with different performance are required in different applications, and should not be mixed, abused or misused to eliminate unnecessary damage and ensure product performance.

3、 Design example of capacitor step-down power supply

The conventional method of converting AC mains power into low-voltage DC power is to use a transformer to step down voltage and then rectify and filter. When limited by factors such as volume and cost, the simplest and practical method is to use a capacitor step-down power supply.

1. Circuit principle of capacitor step-down power supply

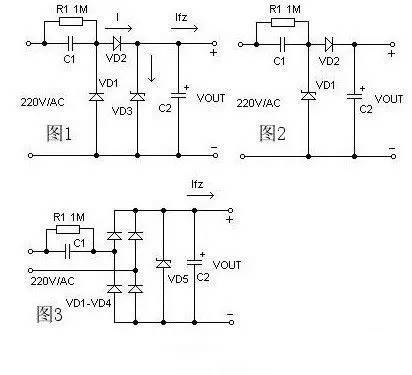

The basic circuit of the capacitor step-down simple power supply is shown in Fig. 1. C1 is a step-down capacitor, D2 is a half wave rectifier diode, D1 provides a discharge circuit for C1 during the negative half cycle of the mains power, D3 is a zener diode, and R1 is the charge discharge resistance of C1 after the power supply is turned off. The circuit shown in Fig. 2 is often used in practical applications. When a large current needs to be supplied to the load, the bridge rectifier circuit shown in Fig. 3 can be used. The unregulated DC voltage after rectification is generally higher than 30V, and will fluctuate greatly with the change of load current. This is due to the large internal resistance of this type of power supply, so it is not suitable for high current power supply applications.

2. Principle of device selection of resistance capacitance step-down circuit

(1) During circuit design, the accurate value of load current shall be measured first, and then the capacity of step-down capacitor shall be selected by referring to examples. Excess current will flow through the regulator. If the maximum allowable current idmax of the regulator is less than IC IO, it is easy to burn the regulator.

(2) In order to ensure the reliable operation of C1, its withstand voltage shall be greater than twice the power supply voltage.

(3) The discharge resistor R1 must be selected to discharge the charge on C1 within the required time.

3. Design examples

In Figure 2, C1 is known to be 0.33 μ F. The AC input is 220V / 50Hz, and the maximum current that the circuit can supply to the load is obtained.

The capacitive reactance XC of C1 in the circuit is: XC = 1 / (2 π f c) = 1 / (2 * 3.14 * 50 * 0.33 * 10-6) = 9.65k the charging current (IC) flowing through capacitor C1 is: ic = u / XC = 220 / 9.65 = 22mA.

Generally, the relationship between the capacity C of the step-down capacitor C1 and the load current IO can be approximated as: C = 14.5 I, where the capacity unit of C is μ F. The unit of IO is a.

|

Disclaimer: This article is transferred from other platforms and does not represent the views and positions of this site. If there is any infringement or objection, please contact us to delete it. thank you! |